Blog Layout

Maximising Return on Investment with Advanced Asset Monitoring

Ian Jansen • Nov 12, 2023

In the dynamic and ever-evolving mining industry, efficiency and optimisation are not just goals; they are imperatives for survival and growth. The key to achieving these objectives lies in the effective management and monitoring of mining assets. With the advent of Simbio Asset Monitoring, mining companies now have access to a sophisticated solution that provides comprehensive insights into their assets, both fixed and mobile, light and heavy. This integration of OEM asset health systems and location tracking ensures that every asset is maximising its return on investment (ROI), whether it’s working on the surface or deep underground.

The Critical Role of Asset Monitoring

Asset monitoring in the mining industry is crucial for several reasons. First, it ensures the effective utilisation of equipment, which is often a significant investment for mining companies. By having accurate, real-time data on the health and location of each piece of equipment, companies can optimise their use and extend their life cycle. This not only saves money in terms of capital expenditure but also reduces operational costs associated with maintenance and downtime.

Second, asset monitoring plays a vital role in the safety of mining operations. Real-time data can help identify potential equipment failures before they occur, preventing accidents and ensuring the safety of the workforce. This aspect is particularly crucial in an industry where the work environment can be hazardous, and the consequences of equipment failure can be severe.

The Technology Behind Simbio Asset Monitoring

Simbio Asset Monitoring utilises state-of-the-art technology to provide comprehensive insights into mining equipment. The system integrates OEM asset health systems and location tracking, offering a detailed view of each asset’s performance and condition.

Future Trends in Mining Asset Management

Looking to the future, the trend in mining asset management is towards even greater integration and automation. The use of Internet of Things (IoT) technology is expected to grow, with more devices and equipment being connected to the internet. This will allow for even more detailed and accurate monitoring of assets.

In addition, advances in artificial intelligence (AI) and machine learning are likely to play an increasing role in asset monitoring. These technologies can be used to analyse the vast amounts of data generated by monitoring systems, identifying patterns and predicting equipment failures before they occur.

Asset monitoring in the mining industry is crucial for several reasons. First, it ensures the effective utilisation of equipment, which is often a significant investment for mining companies. By having accurate, real-time data on the health and location of each piece of equipment, companies can optimise their use and extend their life cycle. This not only saves money in terms of capital expenditure but also reduces operational costs associated with maintenance and downtime.

Second, asset monitoring plays a vital role in the safety of mining operations. Real-time data can help identify potential equipment failures before they occur, preventing accidents and ensuring the safety of the workforce. This aspect is particularly crucial in an industry where the work environment can be hazardous, and the consequences of equipment failure can be severe.

Enhancing Productivity and Profitability

The primary benefit of effective asset monitoring is increased productivity. By ensuring that equipment is in good working order and optimally utilised, mining operations can run more smoothly and efficiently. This leads to increased output and, ultimately, higher profitability.In addition, the data gathered through asset monitoring can be used to make informed decisions about maintenance schedules, equipment replacement, and investment in new technology. This strategic approach to asset management can further enhance the efficiency and profitability of mining operations.

Simbio Asset Monitoring utilises state-of-the-art technology to provide comprehensive insights into mining equipment. The system integrates OEM asset health systems and location tracking, offering a detailed view of each asset’s performance and condition.

One of the key features of the system is its ability to monitor a wide range of assets. From heavy machinery like excavators and dump trucks to smaller, mobile equipment, Simbio Asset Monitoring can track and report on all types of mining assets. This capability is crucial in an industry where a diverse range of equipment is used.

Looking to the future, the trend in mining asset management is towards even greater integration and automation. The use of Internet of Things (IoT) technology is expected to grow, with more devices and equipment being connected to the internet. This will allow for even more detailed and accurate monitoring of assets.

In addition, advances in artificial intelligence (AI) and machine learning are likely to play an increasing role in asset monitoring. These technologies can be used to analyse the vast amounts of data generated by monitoring systems, identifying patterns and predicting equipment failures before they occur.

16 May, 2024

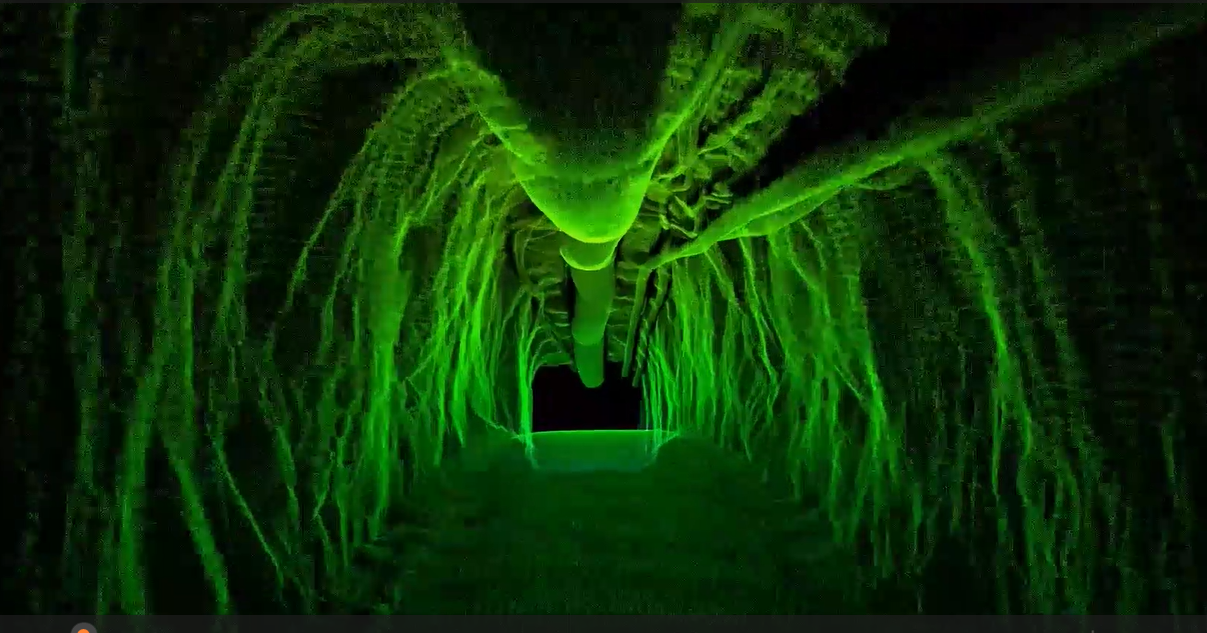

An accurate Digital model for the main decline of an underground mining operation is important and offers valuable benefits for mining companies and operators. From optimising resource extraction to enhancing safety protocols, the meticulous mapping of main declines serves as a cornerstone for efficient and sustainable mining practices. Let's explore some of the key advantages and benefits: 1. Enhanced Safety Protocols: Accurate mapping of the main decline enables mining companies to identify potential safety hazards such as unstable ground conditions, geological faults, or reinforcement movements. By proactively addressing these risks, mining operators can implement robust safety protocols, reducing the likelihood of accidents or incidents and ensuring the well-being of personnel working in the area. 2. Improved Resource Optimization: Mapping the main decline provides valuable insights into the geological characteristics and mineralization patterns of the surrounding ore body. This information allows mining engineers to optimise resource extraction strategies, including the design of mining methods, stope layouts, and ore handling systems. By maximising resource recovery while minimising waste, mining companies can enhance operational efficiency and profitability. 3. Enhanced Operational Planning: Accurate mapping of the main decline facilitates comprehensive operational planning, including scheduling of drilling, blasting, and extraction activities. By visualising the spatial layout of the decline and associated infrastructure, mining operators can optimise workflows, streamline logistics, and minimise downtime, leading to improved productivity and cost-effectiveness. 4. Facilitates Infrastructure Development: Detailed mapping of the main decline provides essential data for the design and construction of infrastructure such as ventilation systems, service lines into the operation, and support structures. By accurately assessing the spatial constraints and geological conditions of the decline, mining engineers can optimise the layout and configuration of infrastructure elements, ensuring efficient operation and maintenance throughout the mine's lifespan. 5. Supports Regulatory Compliance: Mining companies are subject to stringent regulatory requirements governing safety, environmental protection, and resource management. Accurate mapping of the main decline helps ensure compliance with these regulations by providing comprehensive documentation of underground workings, geological features, and safety measures undertaken. This enables mining operators to demonstrate due diligence and accountability to regulatory authorities and stakeholders. Mapping the main decline of a mining operation is a strategic imperative that yields a multitude of benefits that Digital Terrain know and understand. By leveraging the insights gained from a digital twin generated through our Lidar services that seamlessly rolls into Maptek, Deswik and other mining software, mining managers and operators can navigate the path to success with confidence and foresight. Digital Terrain Digital Terrain have solutions that replace or augment existing capabilities for capturing, processing, analysis and reporting. We also offer onsite instruction and training where customers seek to build their own expertise. Enjoy the sample video of our capabilities and contact David Juany for any comments, questions, or service information. david.Jaunay@digitalterrain.io or +61434317580 #lidar #autonomousdrones #slam #hovermap #scanning #underground #stope

By Ryan Landers

•

13 May, 2024

Underground mining is a harsh environment to operate in, where the next decision can be the difference between continued progress or productivity halting delays. Often it is the ‘gut-feel’ or ‘intuition’ that results in pulling Lever A as opposed to Lever B, but when it is estimated that the average adult makes 35,000 decisions a day (Sollisch 2016), it is clear that not all of these can possibly be the optimal solution all of the time. Traditionally, data collection has been a lagged, cumbersome process, fraught with inaccuracies (poor radio communications, misplaced/damaged/destroyed paperwork), double handling (horizontally integrated systems) and delays (data entry occurs progressively by site administration on the following shift for the one preceding it). However, with the advent of digitization, this narrative is rapidly changing. Real-time data collection and analysis empower stakeholders to access accurate and timely information, enabling them to make informed de cisions on the fly. Coupled with Digital Terrain’s RDI-WRS Wireless Repeater System ( https://www.digitalterrain.io/revolutionising-underground-mining-with-wi-fi-mesh-technology ), Simbio PLOD can present decision makers within your business the information they need to execute your plans and achieve your goals. Digital Terrain‘s Simbio Core Suite (SCS) puts frontline personnel at the heart of their solution. Operators are empowered to capture their own data, in real-time, through the use of the Simbio PLOD app (available on Android and iOS). Each operator logs the progress of their shift as they complete their assigned tasks (using Simbio’s PLAN module) including Task Workplace Inspections (Take 5’s, Stop and Thinks, Safe Stops etc), Prestarts, Hazard Forms, Productive Time, Downtime, Maintenance Faults, Trigger Action Response Plan (TARP) workflow escalations and more. The Digital Terrain team is committed to ensure that your operation can hit the ground running from Day 1.